Scientists Make X-Ray To Peep Inside 3D Printed Designs And See If They’re Strong

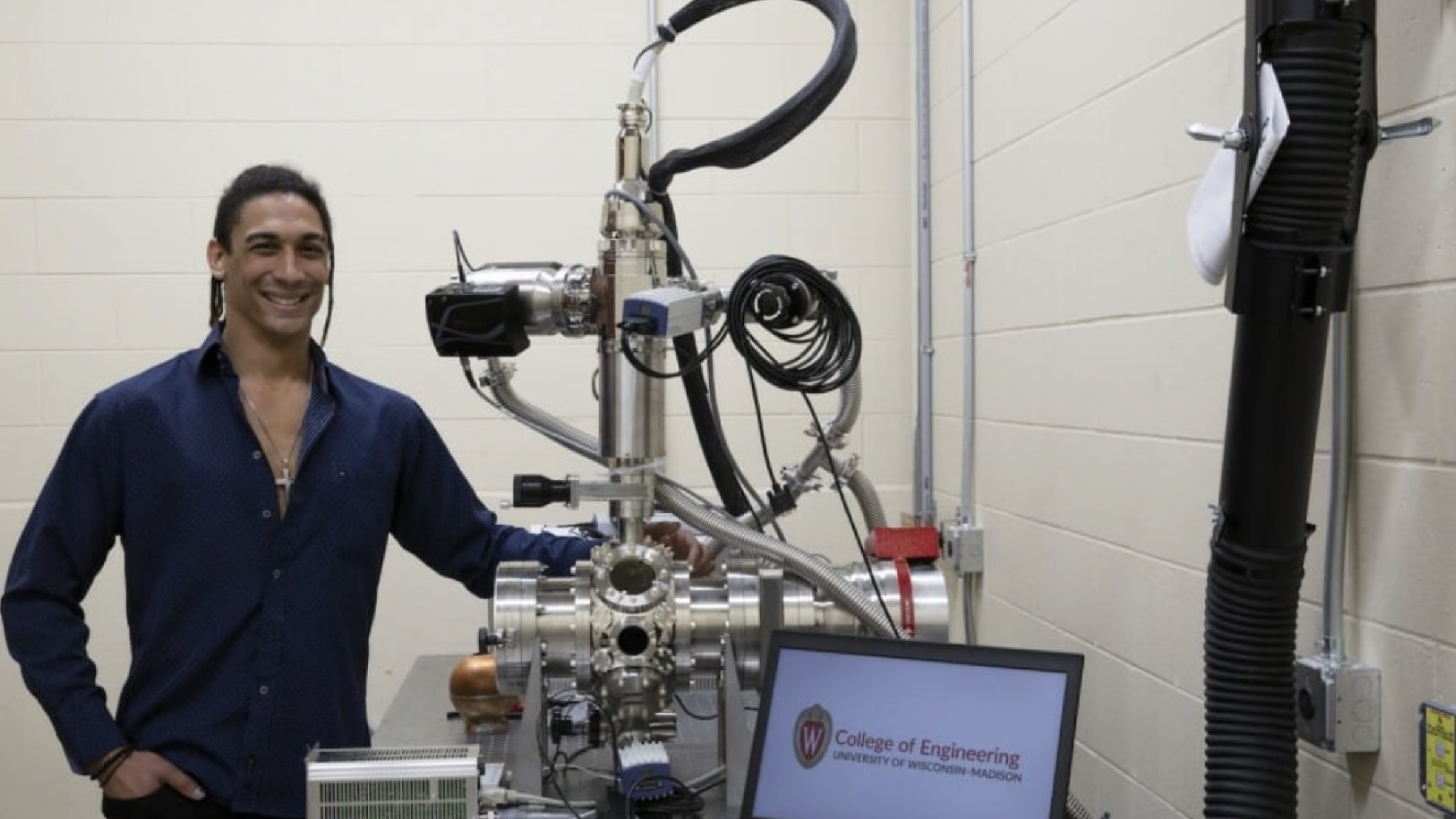

It is now possible to unravel the structural design of 3D-printed metal parts and objects. Engineers at the University of Wisconsin-Madison developed a unique x-ray device to see through 3D printed metal parts. The device will help in determining the structural rigidity of 3D printed designs.

About the imaging device

The whole system incorporates synchrotron X-ray imaging and diffraction along with a thermal camera and a light camera. Engineers at the University of Wisconsin-Madison developed it from scratch and tested it in January.

According to one of the graduate engineers Luis Ezet Escano, it was difficult to combine so many apparatus to build a single piece of equipment. Moreover, it was increasingly challenging to measure its efficacy. But the results were more than satisfactory and it is now a groundbreaking invention in the 3D printing industry.

Xinhang Zhang, Qilin Guo, William Dong, and Minglei Qu were fellow graduate students who assisted Luis. Samuel J. Clark and Kamel Fezzaa, two beamline scientists helped with the group’s synchrotron X-ray experiments. The team was successful in the first attempt itself.

What will scanning 3D printing designs accomplish?

3D printing is used to render and manufacture parts and joints that cannot be forged by hand. Due to varying complexity and a lot of intricate parts, 3D printing is a desirous choice. These printers are used to produce repair parts for rovers sent to other planets. They are lightweight to transport and accurate in construction.

But manufacturing a part using this technique has a fatal flaw. It is impossible to know how strong it is and will it last long. There was no means to scan a 3D printed part and scan its layers. But with the imaging tool developed and the University of Wisconsin-Madison, it is now possible. Engineers can look deep into the layers of metal compounds used to create a design. They can learn about the weak areas of such designs and develop a stronger 3D printing compound.

This scanning device will elevate the automated printing industry and will scale up its usage on an exponential level. You can read the detailed report published by the University of Wisconsin–Madison here.